The Star That Faded

Chosen as Motor Trend’s Car of the Year in 1971, GM’s Chevrolet Vega was named after constellation Lyra’s brightest star and started off strong—but its reputation plummeted by the time production ended with its 1977 model, with the vehicle and GM’s reputation in tatters.

Choices Made And Offered

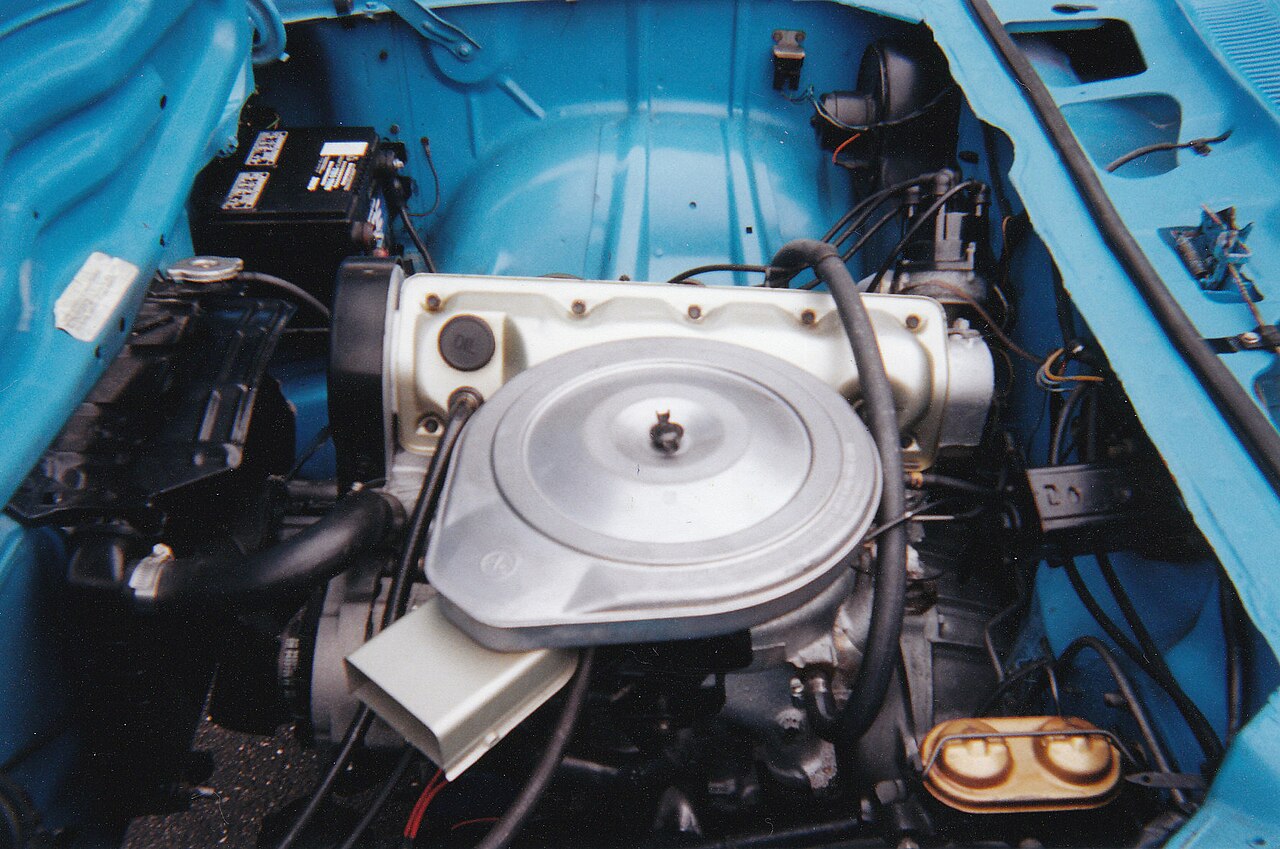

This subcompact automobile first went on sale in September 1970, and came with a lot of body options: two-door hatchback, notchback, wagon, and sedan delivery. But there was only one lightweight motor designed just for the Vega: a four-cylinder engine made out of aluminum.

Barnstarbo, CC BY-SA 3.0, Wikimedia Commons

Barnstarbo, CC BY-SA 3.0, Wikimedia Commons

Plans Set In Motion

In 1967, a vice-president at GM, Ed Cole, successfully lobbied for his version of a small car that the company could use to enter this potentially lucrative market. Rejecting Chevrolet engineers’ own design, GM Chairman James Roche announced in 1968 that the car would be on sale by 1970.

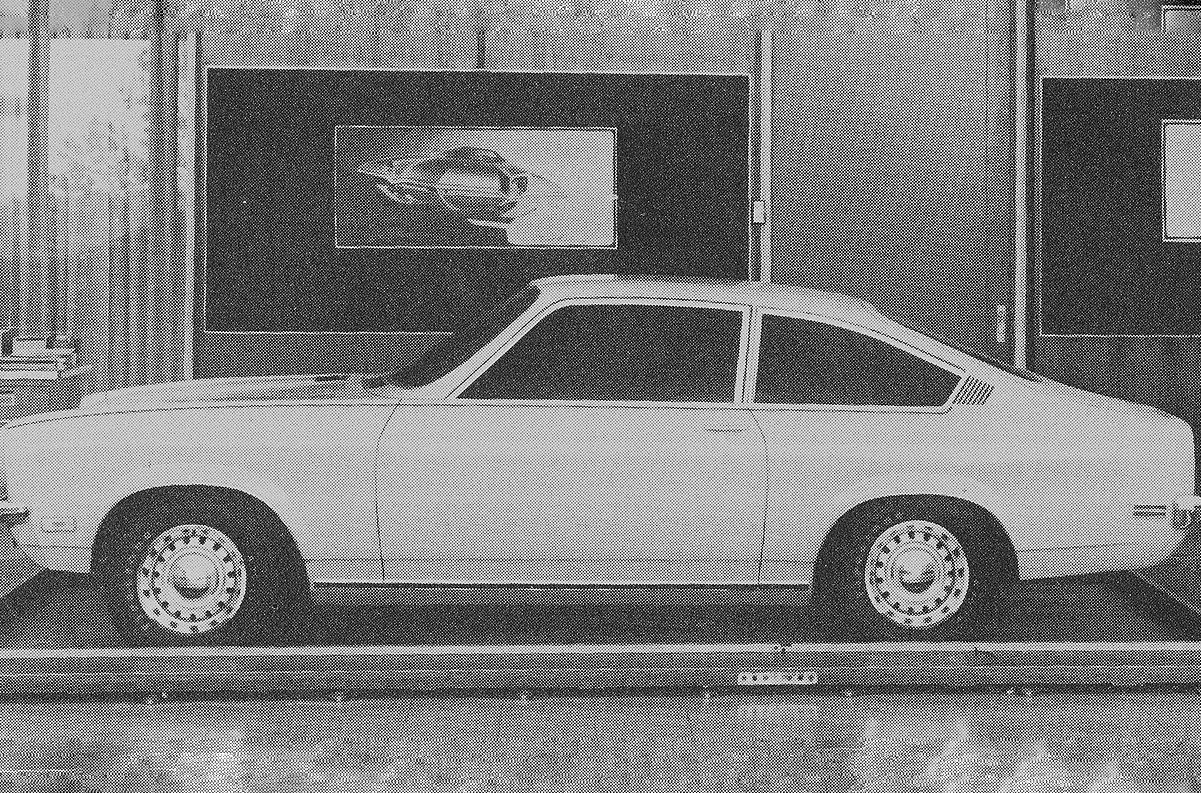

wallerdog, CC BY-SA 3.0, Wikimedia Commons

wallerdog, CC BY-SA 3.0, Wikimedia Commons

Early Hype

Roche claimed “stylists, researchers, and engineers” were already working on this car with a code name of XP-877, though GM executive John DeLorean later said little had been done to that point, aside from collecting blueprints of various models made overseas.

Team Effort

A design team led by James G Musser Jr started work, with Musser later saying never before had a single team led by one person designed a whole vehicle, which included testing their concept of a reasonably large displacement engine the equivalent of 6 million miles.

Block Planning

The engine was designed to have low engine rpm for better fuel economy, so low-speed torque and the right gear ratios were essential. A prototype aluminum engine block was installed in a number of 1968 Opel sedans to tweak the motor’s design.

Robert Spinello, CC BY-SA 3.0,Wikimedia Commons

Robert Spinello, CC BY-SA 3.0,Wikimedia Commons

Work Continues

By the end of 1968, the notchback sedan, hatchback, wagon, and sedan delivery styles were completed. Through 1969, work proceeded on transmissions, in-tank electric pumps, power steering (an option), suspension, wider tires, and more. Production began in June 1970.

Chevrolet pre-1978, Wikimedia Commons

Chevrolet pre-1978, Wikimedia Commons

It Was “In Trouble” From The Beginning

But as DeLorean notes, GM brass had imposed the Vega on Chevrolet with its engineers having to get the model ready for production, but having little say over the design. “From the first day I stepped into Chevrolet, the Vega was in trouble,” he noted later.

MercurySable99, CC BY-SA 4.0, Wikimedia Commons

MercurySable99, CC BY-SA 4.0, Wikimedia Commons

An Underwhelming Performance

Initial reception was mostly positive, with some reviewers praising the car’s handling. But early on, it became clear that GM had overpromised and underdelivered.

Chevrolet pre-1978, Wikimedia Commons

Chevrolet pre-1978, Wikimedia Commons

Drivers As QA Testers

As Cars magazine wrote in 1974, by rushing out the inaugural 1971 model, customers ended up doing the quality testing that should have been done in the development process, forcing dealers to fix these initial problems.

Alarming Features

Whatever the pros and cons with the car’s design, problems with quality control overwhelmed the positives. As GM cut corners, rear axles would separate and tires would fall off cars.

Motoring On

Chevrolet engineers who’d promoted an iron-block engine must’ve looked on in horror at reports that the overall power unit was melting due to poor cooling and other issues. Meanwhile, GM tried to make design changes to set things right.

Tackling Problems

Models for 1972 tackled vibration and noise issues with a redesigned exhaust system, driveline, and shock absorbers. A three-speed automatic transmission was offered as an option.

dave_7, CC BY 2.0, Wikimedia Commons

dave_7, CC BY 2.0, Wikimedia Commons

A Million Vegas

For the 1973 model, there were around 300 interior and exterior changes. The front bumper was extended to meet new safety standards, and Sanginaw manual transmissions replaced Opel’s units. In May 1973, the Lordstown Assembly plant shipped its millionth Vega.

Barnstarbob, CC BY-SA 3.0, Wikimedia Commons

Barnstarbob, CC BY-SA 3.0, Wikimedia Commons

Fender Benders

The 1974 model strengthened the bumpers some more, and boosted the fuel tank from 11 gallons to 16. Plastic front fender lines were added after thousands of fenders were replaced under warranty since the Vega had been introduced.

Robert Spinello, CC BY-SA 3.0, Wikimedia Commons

Robert Spinello, CC BY-SA 3.0, Wikimedia Commons

Limited Edition

High-energy electronic ignition and a catalytic converter were added for the 1975 model, with the limited-edition Cosworth Vega offering Chevrolet’s first passenger car with electronic fuel injection.

User:Morven, Wikimedia Commons

User:Morven, Wikimedia Commons

Cooling Things Down

The 1976 model attempted to improve the Dura-Built 2.3 L engine’s cooling system, and a five-speed manual overdrive transmission was offered as an option.

End Of The Line

The final year’s model saw relatively few revisions, with some cosmetic changes and a pulse-air system on the Dura-built 140 engine to meet tougher emission standards.

Robert Spinello, CC BY-SA 3.0, Wikimedia Commons

Robert Spinello, CC BY-SA 3.0, Wikimedia Commons

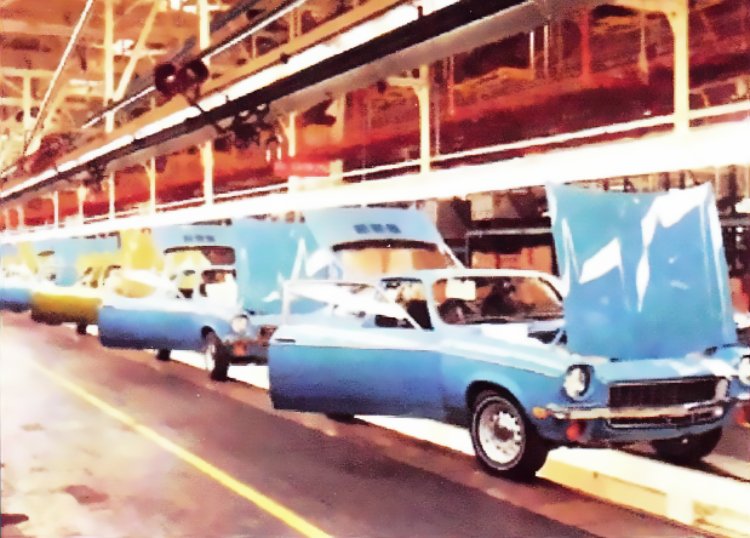

Computers Are Key

But getting back to how this all started, GM saw computerization as the key to making Vega production as cheap and efficient as possible, so they built a brand-new assembly plant in Lordstown, Ohio, just to make this model line.

Welding Robots

It was touted as the most automated vehicle plant in the world, with the Vega’s welds performed by a combination of Unimate industrial robots and conventional automatic welders. Engine and rear-axle assemblies moved along at 30 feet per minute.

Robert Spinello, CC BY-SA 3.0, Wikimedia Commons

Robert Spinello, CC BY-SA 3.0, Wikimedia Commons

Speed Demons

The initial goal was to produce 100 Vegas every hour, which would be twice a car’s normal production rate, and definitely the fastest in the world. Within a few months, the Lordstown plant was producing 73.5 vehicles per hour.

dave_7, CC BY 2.0,Wikimedia Commons

dave_7, CC BY 2.0,Wikimedia Commons

Layoffs And The Blame Game

Though there were flaws, the assembly quality was seen as acceptable. Trouble loomed when GM switched plant management to the General Motors Assembly Division, which dropped one member from each four-member team, laid off workers, and blamed those remaining for sabotaging production.

Strike And Speed

In March 1972, workers went on a wildcat strike for a month, but the company still managed to produce 100,000 Vegas that year. By 1975, the factory was producing 100 cars per hour.

MercurySable99, CC BY-SA 4.0, Wikimedia Commons

MercurySable99, CC BY-SA 4.0, Wikimedia Commons

New Solutions

But as production speed increased, conventional paint techniques broke down—but Fisher Body and DuPont quickly figured out a workaround.

Still Cheap

By the end of its production, around 2 million Vegas were built, mostly in the Lordstown plant. The basic model started off at $2,090 in 1971, and went up to $3,249 as 1977 came to an end. Inflation was hitting more expensive cars too, which helped boost the attraction of the Vega’s lower price.

Unknown Author, Wikimedia Commons

Unknown Author, Wikimedia Commons

Simmering Doubts

GM vice-president John Delorean, who was also Chevrolet’s general manager, later said he’d tried to tackle quality issues with more inspectors and assembly workers, but admitted he was pressured to promote the car “beyond my personal convictions about it”.

Bernard Gotfryd, Wikimedia Commons

Bernard Gotfryd, Wikimedia Commons

Early Recalls

In 1972, GM had to issue three recall notices due to problems with axles and throttles, plus potential fire hazards. The Vega’s engine was prone to buckle and leak. By May of that year, six Vegas out of seven were affected by recalls.

Feeling The Heat

The Vega’s engine would often overheat, warping the cylinders and peeling silica from piston rings. Oil and coolant often ran low at the same time, allowing antifreeze to infiltrate the head gasket.

Barnstarbob, CC BY-SA 3.0, Wikimedia Commons

Barnstarbob, CC BY-SA 3.0, Wikimedia Commons

Putting It Right

In 1974, Chevrolet offered to retrofit earlier models for free with a coolant-overflow bottle and electronic low-coolant indicator, an offer that cost Chevrolet a lot of money.

dave_7, CC BY-SA 2.0, Wikimedia Commons

dave_7, CC BY-SA 2.0, Wikimedia Commons

Faulty One Way Or Another

Was overheating even the fundamental problem? One GM engineer said the underlying issue was a combination of poor valve stem seals and piston plating. Either way, customers—or their mechanics—were seeing a lot of damaged cylinder walls.

Barnstarbob, CC BY-SA 3.0, Wikimedia Commons

Barnstarbob, CC BY-SA 3.0, Wikimedia Commons

A Corrosive Effect

Early models had poor rustproofing due to an air pocket in one of the vats containing the anti-rust coating, allowing salt and debris to build up and rust to spread behind the front fenders. GM’s accountants had rejected protective liners as they’d cost a little over two dollars each.

Barnstarbob, CC BY-SA 3.0, Wikimedia Commons

Barnstarbob, CC BY-SA 3.0, Wikimedia Commons

Rust Stays In Vegas

GM added plastic deflectors in late 1973 and 1974, but it cost the company millions of dollars to repair rust in Vegas without them. Other rust-prone points included rocker panels, door bottoms, the bottom of windshields, and the body above rockers.

Barnstarbob, CC BY-SA 3.0, Wikimedia Commons

Barnstarbob, CC BY-SA 3.0, Wikimedia Commons

The Known Unknown

Customers in places like California and Arizona, normally nearly rust free, were complaining about their cars being attacked by corrosion. Things were eroding fast, including GM’s reputation.

It Started Off So Well

Things had initially looked good for the Vega, with favorable comparisons to competitors such as the Ford Pinto, the Volkswagen Beetle, and the Toyota Corolla. But consumer advocate Ralph Nader criticized the car early on as a poor example of car production.

JOHN LLOYD, CC BY 2.0, Wikimedia Commons

JOHN LLOYD, CC BY 2.0, Wikimedia Commons

Self-Destruction

Later commentators heartily agreed, saying the Vega became “a symbol of all the problems Detroit faced in the 70s”. Its Achilles heel was an engine block that “self-destructed all too easily, and all too often”. One critic said the Vega was "the car that nearly destroyed GM".

Vegavairbob, CC BY-SA 3.0,Wikimedia Commons

Vegavairbob, CC BY-SA 3.0,Wikimedia Commons

Junkyard Reject

Legend has it that one scrapyard put up a “No Vegas” sign, indicating the car wasn’t even worth scavenging for parts before being crushed into a metal pancake. Few Vegas are seen on the roads today.

Vegavairbob, CC BY-SA 3.0, Wikimedia Commons

Vegavairbob, CC BY-SA 3.0, Wikimedia Commons

Divisions Multiply

GM’s cost-cutting and corporate arrogance ultimately tore into its profits and credibility, with internal divisions and top-heavy centralization stifling innovation and quality control.

Barnstarbob, CC BY-SA 3.0, Wikimedia Commons

Barnstarbob, CC BY-SA 3.0, Wikimedia Commons

Pattern Repeated

Critics say GM later repeated its habit of taking good ideas and ruining them with engineering issues or poor-quality assembly, as with the Oldsmobile 350 diesel V-8 (1978) and its X-platform cars (1980). GM’s attempt at creating a bold vision with its Saturn cars also floundered under internal strife and pressure.

Back On Track

These problems seemed to come to a head with the company’s dramatic restructuring in 2009, which saw the US government massively invest in the company to prevent its bankruptcy. The company has since recovered, and is now ranked 25th by revenue on the Fortune 500.

Robert Spinello, CC BY-SA 3.0, Wikimedia Commons

Robert Spinello, CC BY-SA 3.0, Wikimedia Commons

Driving Into The Sunset

And that’s the tale of the Vega, a car with some welcome features and some good ideas, but doomed by engineering complications and poor quality control. At least, in the end, it left some lessons for automakers everywhere.